|

|

Search Our Site

|

|

|

Oil Analysis Kits

|

|

|

AMSOIL

provides oil analysis service options. By analyzing used engine oil,

a qualified lab can detect mechanical problems your engine may have.

View the AMSOIL Oil Analysis Brochure

Here |

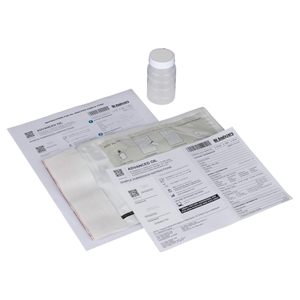

Product Code: KIT01 |

Oil Analyzers Test Kit, Postage

Pre-Paid

Oil Analyzers offers several full-service

lubricant-analysis kits. KIT01 can also be used for all

drivetrain fluids, but use KIT09 for coolant testing.

The testing included with KIT01 includes the following:

- 24 Metals by ICP (wear metals, contaminant

metals, multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT01 includes 3-oz. sample bottle, mailer with USPS

First-Class package label, sample form and instructions.

|

Product Code: KIT02 |

Oil Analyzers Test Kit, UPS Pre-Paid

Oil Analyzers offers several full-service

lubricant-analysis kits. KIT02 can also be used for all

drivetrain fluids, but use KIT09 for coolant testing.

The testing included with KIT02 includes the following:

- 24 Metals by ICP (wear metals, contaminant

metals, multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT02 includes 3-oz. sample bottle, mailer with UPS

pre-paid shipping label, sample form and instructions.

|

Product Code: KIT06 |

Oil Analyzers Test Kit, Non Postage

Paid

Oil Analyzers offers several full-service

lubricant-analysis kits. KIT06 can also be used for all

drivetrain fluids, but use KIT09 for coolant testing.

The testing included with KIT06 includes the following:

- 24 Metals by ICP (wear metals, contaminant

metals, multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT06 includes 3-oz. sample bottle, mailer, sample

form and instructions.

Note: This kit does not

include pre-paid postage. Customer is responsible for

shipping charges.

|

Product Code: KIT09 |

Coolant Testing Kit, UPS Pre-Paid

In addition to lubricant testing, Oil Analyzers also

offers coolant testing. KIT09 can only be used for

coolant. The testing included with KIT09 includes the

following:

- 17 Metals by ICP

- pH

- Glycol % (Ethylene or Propylene Glycol)

- Freeze Point

- Boil Point

- Nitrite

- SCA Number

- Total Dissolved Solids

- Specific Conductance

- Total Hardness

- Visual Examination (color, oil, fuel, magnetic

precipitate, non-magnetic precipitate, odor and

foam)

KIT09 includes 3-oz. sample bottle, mailer with UPS

pre-paid shipping label, sample form and instructions.

|

Product Code: KIT10 |

Diesel Fuel Contamination Test

The Diesel Fuel Contamination Test

Kit tests for water, sediments and aerobic bacteria. KIT10

includes 32-oz. container, UPS pre-paid shipping label,

sample form and instructions.

|

Product Code: KIT11 |

Diesel Fuel Performance Test

The Diesel Fuel Performance Test Kit

tests basic fuel quality, including 24 metals by ICP,

viscosity at 40°C, calculated cetane index, distillation and

API gravity. KIT11 includes 32-oz. container, UPS pre-paid

shipping label, sample form and instructions.

|

Product Code: KIT14 |

Oil Sample Value Kit

Oil Analyzers also offers a less expensive option for

determining the basic condition of oil and whether it

should be changed. The testing included with KIT14

includes the following:

- 24 Metals by ICP (wear metals, contaminant

metals, multi-source metals and additive metals)

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Base Number (Engines)

- Acid Number (Non-Engines)

If you are trying to extend drain intervals or if you

suspect abnormal contamination such as fuel dilution or

water, a full-service kit is required.

KIT14 includes 3-oz. sample bottle, mailer, sample

form and instructions.

Note: This kit does not

include pre-paid postage. Customer is responsible for

shipping charges.

|

Product Code: KIT15 |

Commercial Failure Analysis

Test Kit, Non Postage Paid

FOR COMMERCIAL USE ONLY

Oil Analyzers offers several full-service

lubricant-analysis kits for commercial accounts. KIT15 can

also be used for all drivetrain fluids, but use KIT09 for

coolant. The Oil Analyzers Failure Analysis Program helps

find the root cause of equipment failures through used-oil

analysis and Oil Analyzers Inc. technical expertise. For

optimal results, use this kit alongside equipment

disassembly and parts inspection, review of maintenance

records (or previous oil analysis) and other failure

analysis tools.

The testing with KIT15 includes the

following:

- 24 Metals by ICP (wear metals, contaminant metals,

multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT15 includes three 3-oz. sample bottles, three sample

test forms, three mailers, a vacuum pump, 25’ sample tubing

and

instructions.

Note: This kit does not include pre-paid postage.

Customer is responsible for shipping charges.

|

Product Code: KIT16

|

Commercial Maintenance Improvement

Test Kit, Non Postage Paid

FOR COMMERCIAL USE ONLY

Oil Analyzers offers several full-service

lubricant-analysis kits for commercial accounts. KIT16 can

also be used for all drivetrain fluids, but use KIT09 for

coolant. The Oil Analyzers Maintenance Improvement Program

helps keep your critical equipment operating efficiently for

longer periods of time, helping you find, diagnose and

correct major issues before they result in critical failures

and unplanned downtime. Oil analysis is a practical and

effective maintenance practice, requiring minimal equipment

downtime while providing exceptional insight into critical

component operation and health. This kit is designed for

sampling one equipment component (engine,

transmission, compressor, hydraulics, etc.).

The

testing with KIT16 includes the following:

- 24 Metals by ICP (wear metals, contaminant metals,

multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT16 includes four 3-oz. sample bottles, four sample

test forms, four mailers, a vacuum pump, 25’ sample tubing

and

instructions.

Note: This kit does not include pre-paid postage.

Customer is responsible for shipping charges.

|

Product Code: KIT17 |

Commercial Drain Interval

Improvement Test Kit, Non Postage Paid

FOR COMMERCIAL USE ONLY

Oil Analyzers offers several full-service

lubricant-analysis kits for commercial accounts. KIT17 can

also be used for all drivetrain fluids, but use KIT09 for

coolant. Oil analysis and the information provided by Oil

Analyzers Inc. lubrication experts gives insight into

extending oil drain intervals based on the condition of

used-oil samples. It also provides information on key

physical properties (viscosity, total base number,

oxidation) that indicate whether the oil is suitable for

continued service. This kit is designed to safely establish

extended intervals for one piece of

equipment.

The testing with KIT17 includes the following:

- 24 Metals by ICP (wear metals, contaminant metals,

multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT17 includes four 3-oz. sample bottles, four sample

test forms, four mailers, a vacuum pump, 25’ sample tubing

and

instructions.

Note: This kit does not include pre-paid postage.

Customer is responsible for shipping charges.

|

Product Code: KIT18 |

All-In-One Sample Kit, Non-postage

Paid

The All-In-One sample kit combines everything needed to

pull used oil samples in a convenient all-in-one kit. Kit

includes a vacuum sample pump, 25 feet of sample tubing,

three sample bottles and three oil-analysis tests (same test

package included with the OAI Full-Service Kits). This kit

can be used for all drivetrain fluids, but cannot be used

for coolant. Pull three samples from one vehicle (engine,

differential, transmission) or three samples from multiple

vehicles; the choice is yours.

The testing with KIT18 includes the following:

- 24 Metals by ICP (wear metals, contaminant metals,

multi-source metals and additive metals)

- % Fuel Dilution (Engines)

- % Soot (Engines)

- Water % by Crackle

- Viscosity @ 40°C (Non-Engines)

- Viscosity @ 100°C (Engines)

- Oxidation/Nitration

- Base Number (Engines)

- Acid Number (Non-Engines)

KIT18 includes three 3-oz. sample bottles, three sample

test forms, three mailers, a vacuum pump, 25’ sample tubing

and

instructions.

Note: This kit does not include pre-paid postage.

Customer is responsible for shipping charges.

|

Product Code:

G1206 |

Oil Analysis Pump

Note: This Sampling Pump includes 10'

of hose. The Oil Analysis Kits contain the Bottle (kits sold

separately).

|

Product Code:

G1571 |

Replacement Hose-25 Ft.

G1571 Replacement Hose-25 Ft. for OAI

Pump

|

|

|

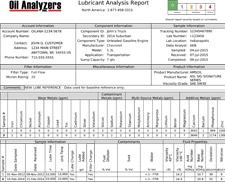

The Sampling Process

Trend Analysis

A

single sampling analysis is useful in providing information when

critical failure conditions exist. However, trend analysis is a

better tool for estimating the useful life or overall condition of

your engine or equipment. Trend analysis samples are taken and

analyzed at regularly scheduled intervals. Comparing the most recent

analysis to previous reports on a given machine shows the

development of trends. Monitoring these trends enables early

detection of internal abnormalities. Tested values falling within

acceptable limits may show a pattern of subtle variance, which could

signal a developing problem. A

single sampling analysis is useful in providing information when

critical failure conditions exist. However, trend analysis is a

better tool for estimating the useful life or overall condition of

your engine or equipment. Trend analysis samples are taken and

analyzed at regularly scheduled intervals. Comparing the most recent

analysis to previous reports on a given machine shows the

development of trends. Monitoring these trends enables early

detection of internal abnormalities. Tested values falling within

acceptable limits may show a pattern of subtle variance, which could

signal a developing problem.

Machines of

the same type will accumulate contaminants and wear at different

rates. Performing trend analysis on each machine is the most

effective method of giving you an internal look at your equipment

and enabling you to deal with developing problems before they become

catastrophic situations.

Sampling Frequency

The frequency of sample analysis from your equipment depends on the

machine type, machine application and condition, operating

environment and other variables. For example, many machines that

operate in harsh environments, such as heavy equipment in mining or

construction, require short oil sampling intervals - every 100 to

300 operating hours. However, certain power transmission systems,

such as gearboxes and hydraulic systems used inside manufacturing

and production facilities, require no more than quarterly sampling

intervals. The following table lists generic sampling frequencies

for common equipment types, and is provided as a guideline only.

Additional information is available from

www.oilanalysis.us, your

lubricant supplier, and the equipment manufacturer.

Collecting a

clean and representative oil sample is critical to the oil analysis

process. Put simply, an oil analysis is only as good as the sample

taken. The accuracy and reliability of the data produced by an

analysis hinges on receiving a representative sample from the

equipment to be tested. To assure that the sample extracted is

representative of the system, always follow proper sampling

procedures.

Note: Sampling Pump and Hose are

sold separately Buy it Here

See more info

at:

www.oilanalysis.us

|

|

|

|

|