|

Change Gear Lube After Break-In Period For Long

Differential Life

Motorists know when they’re supposed to change their

motor oil. They have owners manuals, oil life monitors,

oil change centers and commercials all telling them when

it’s time for an oil change. Differential oil changes,

on the other hand, often get overlooked. Many people

don’t even think of the differential when performing

routine maintenance on their vehicles and don’t realize

four-wheel drive trucks have two differentials and a

transfer case that all require service. In fact,

according to one quick lube company, only one to two

percent of their customers purchase a differential gear

lube change.

Differential

internal components consist of six gears (one pinion, one ring, two

side and two spider gears), six bearings (two pinion, two carrier

and two axle) and sometimes include a clutch setup for limited slip

performance. All of these parts require high quality, clean gear oil

in order to perform at an optimal level. Differential

internal components consist of six gears (one pinion, one ring, two

side and two spider gears), six bearings (two pinion, two carrier

and two axle) and sometimes include a clutch setup for limited slip

performance. All of these parts require high quality, clean gear oil

in order to perform at an optimal level.

Most pickup trucks, SUVs and vans operate in severe service

conditions, including towing, hauling, steep hill driving,

commercial use, plowing, racing, off-road use, rapid acceleration,

frequent stop-and-go operation and high ambient temperatures. These

severe service operating conditions subject the differential to

extreme pressures and operating temperatures.

New vehicles such as turbo diesel trucks and vehicles with V-10

engines boast more horsepower and torque than their predecessors,

but differential designs have remained virtually unchanged.

Differentials today are subjected to severe duty service and

encounter more stress and heat than was seen only a few years ago.

Modern gear oils are faced with the challenge of providing adequate

wear protection during severe service operating conditions, while

also providing maximum fuel efficiency.

In fact, according to a 2005 SAE paper entitled Breaking the

Viscosity Paradigm: Formulating Approaches for Optimizing Efficiency

and Vehicle Life, “Concurrent with the strong drive toward better

fuel economy, consumers have been demanding increased performance,

which has required axle lubricants with enhanced durability

protection and lower operating temperatures. There has been a 34%

increase in engine horsepower over the last decade, while axle gear

sizes have remained constant, sump capacities have been lowered, and

drain intervals extended. In the light truck segment there has been

a 93% horsepower increase since 1981.”

Most differential wear occurs during the break-in period. Because

differentials are not equipped with filters, break-in metals are

suspended in the oil, causing increased wear as the particles mesh

between the gears. Hauling heavy loads and towing heavy trailers

cause additional stress to the differential during the break-in

period and can cause premature differential damage. Changing the

gear lube after the break-in period (about 5,000 miles) greatly

reduces wear and extends differential gear and bearing life. Auto

manufacturers are beginning to recognize the importance of draining

abrasive break-in materials. As seen in the chart, some

manufacturers recommend an initial drain interval of between 500 and

3,000 miles.

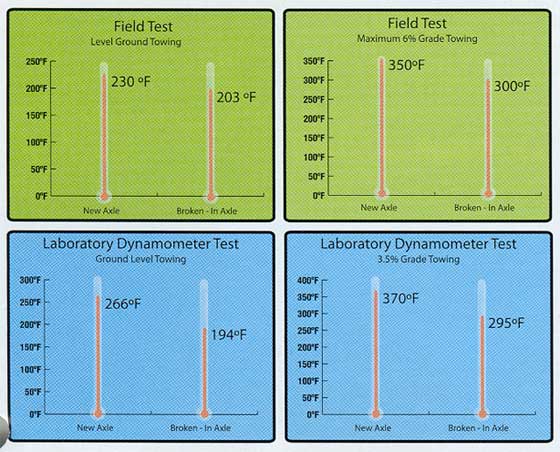

Further evidence of stress and increased temperatures during the

differential break-in period is documented in a 2005 SAE paper

entitled The Effect of Heavy Loads on Light Duty Vehicle Axle

Operating Temperature. A light duty GM truck towing 14,000 pounds

was driven from Orange County, Calif. to the Nevada state line. The

test was conducted with both a new axle and a broken-in axle. Over

level ground towing, oil temperature was measured at 110 degrees F

in the new axle and 95 degrees F in the broken-in axle. Oil

temperature over the most grueling portion of the trip, during which

a maximum 6% grade was encountered, revealed the new axle was

operating at 350 degrees F and the broken-in axle was operating at

300 degrees F. Laboratory dynamometer test results simulating a

truck hauling a trailer provided similar results, with level ground

towing temperatures recorded at 266 degrees F with the new axle and

194 degrees F with the broken-in axle and towing temperatures (at a

3.5% grade) recorded at 370 degrees F with the new axle and 295

degrees F with the broken-in axle.

AMSOIL SEVERE GEAR™ 75W-90,

75W-110, and

75W-140 Synthetic Gear Lubes are

formulated for severe service applications, protecting differential

gears for extended drain intervals of up to 50,000 miles in severe

service and 100,000 miles in normal service, or longer where

specified by the vehicle manufacturer. Formulated with shear stable

synthetic base stocks and an extra treatment of additives, SEVERE

GEAR™ Gear Lubes provide unsurpassed wear protection and friction

reduction, while their excellent thermal stability prevents thermal

runaway, a phenomenon caused by a lubricant’s inability to control

friction and increased heat under high stress conditions.

AMSOIL SEVERE GEAR™ Synthetic Gear Lubes are recommended for

turbo diesel pick-ups, SUVs, vans, delivery/utility vehicles, light,

medium and heavy-duty trucks, buses, heavy equipment, 4x4s, tow

trucks, race cars, tractors and motor homes.

|